Saturne Technology

A few years ago, 3D printers appeared on the market. Walter Grzymlas quickly realised the advantages of this technology and started 3D metal printing. A winning bet in view of the development of Saturne Technology. In 22 years, 23 people have joined the company, which serves customers all over the world.

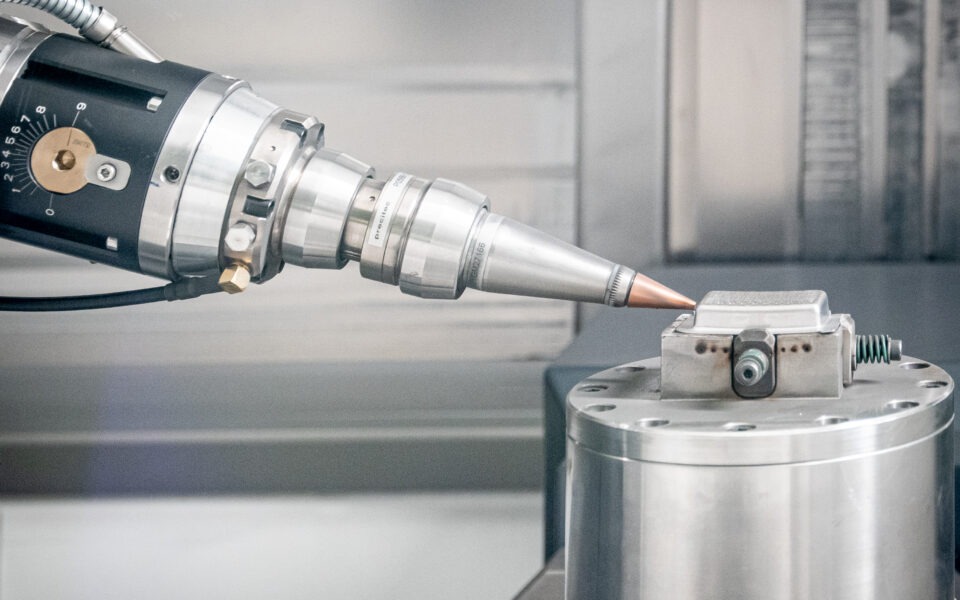

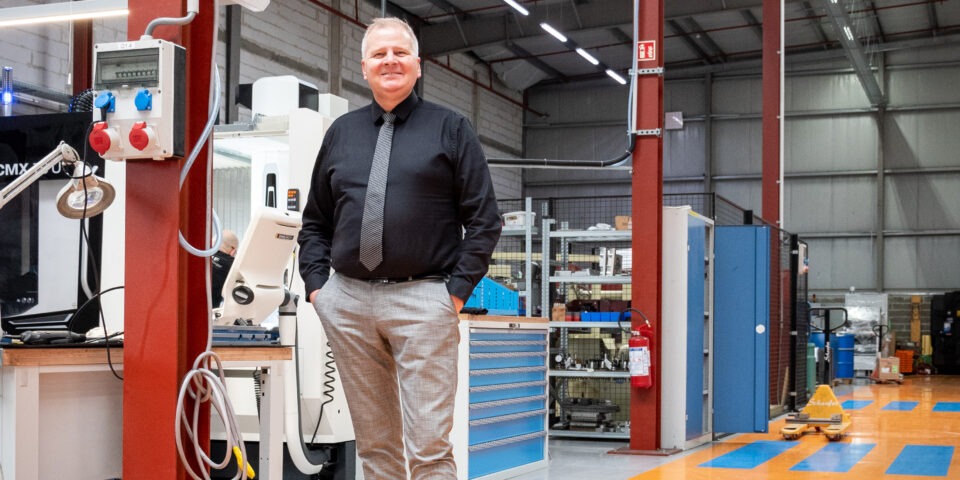

In the 5,000 m2 warehouse that houses Saturne Technology, the machines are running at full speed in an astonishing silence. The company produces metal parts for industry, space, aeronautics and the medical sector. Walter Grzymlas is the head of the company. After graduating with a European degree in materials metallurgy, he began his career as an engineer and then as a production manager, before becoming deputy director of a French company that produces gas turbines for oil platforms. “After several years in this position, I decided to create Saturne Technology in the early 2000s in Luxembourg. When I started the company, I was alone,” explains the founder. In the early years, we specialised in laser welding, laser drilling, laser cladding and laser cutting. This expertise is really the basis of the company. Since then, metal additive manufacturing, or 3D metal printing, has been one of the company’s main services. With five printers and numerous lasers, the order book is still full.

A difficult start

However, it hasn’t always been easy, and Walter Grzymlas never imagined that he would be here 22 years ago. At that time, I would have liked to know where I would be today, that would have helped me a lot,” says the company director. When we arrived, our activity did not exist in the files of the Luxembourg administration. It was difficult, but we finally got the authorisation to set up. The fact that we were working with a laser technology that was still unknown also made it more difficult to obtain financing to develop the company. “The situation was complicated for the first six or seven years. But little by little, we started to qualify different parts for the aeronautics or space industries,” says the man who now heads a company with 23 employees. This means that they meet the standards of the companies and are therefore used throughout the life of the part.

A technological revolution

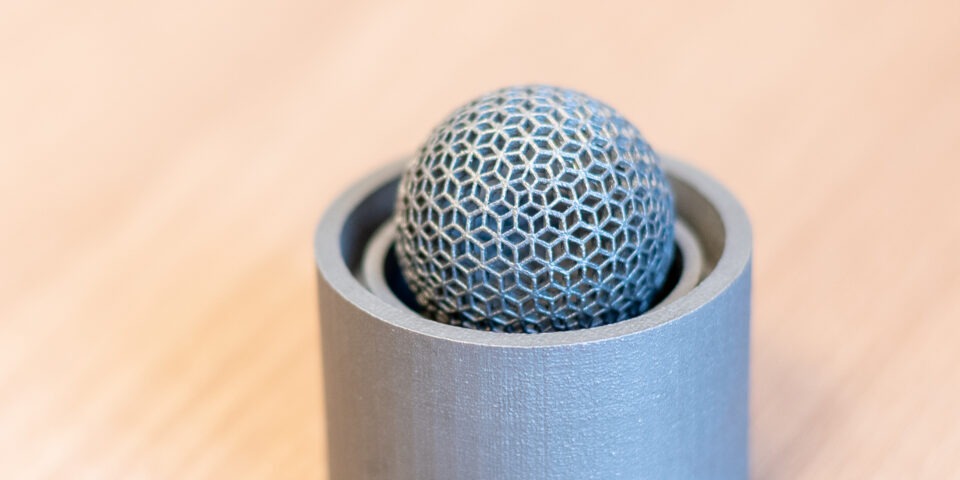

3D printers began to appear in the early 2005s. At that time, it was mainly plastic printing. But right from the start, the founder of Saturn Technology wanted to turn to metal 3D printing. “We went around the world to see what was being done, consulting with designers of metal 3D printing machines,” explains Walter. In 2012, the company acquired its first metal 3D printer, which was also encouraged by its own customers. The latter, active in welding and drilling, needed a tool of this kind for their activity. Saturne Technology then supported them while developing its own metal printing skills. One thing led to another and Saturn Technology’s reputation grew and the company has now reached a real milestone, producing parts for rocket engines, for example. “We are now the only supplier of private microlight engines. This means that there is no intermediary between us and the space or aeronautical companies,” adds the company’s founder.

The future looks just as promising. Recently, Saturne Technology carried out tests for components used in rockets and launchers. The tests were successful, so they will continue to work on these components. The turnover from our space activities – especially the production of engines and satellites – has developed very strongly in recent years,” explains Walter Grzymlas. In the future, Saturne Technology will place more and more emphasis on research and development of new technologies. 3D printing is still in its infancy.